Line Stopping Service

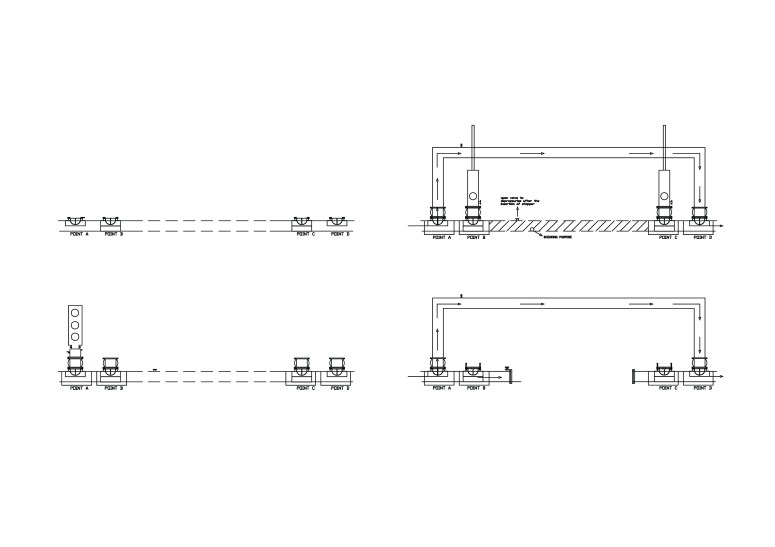

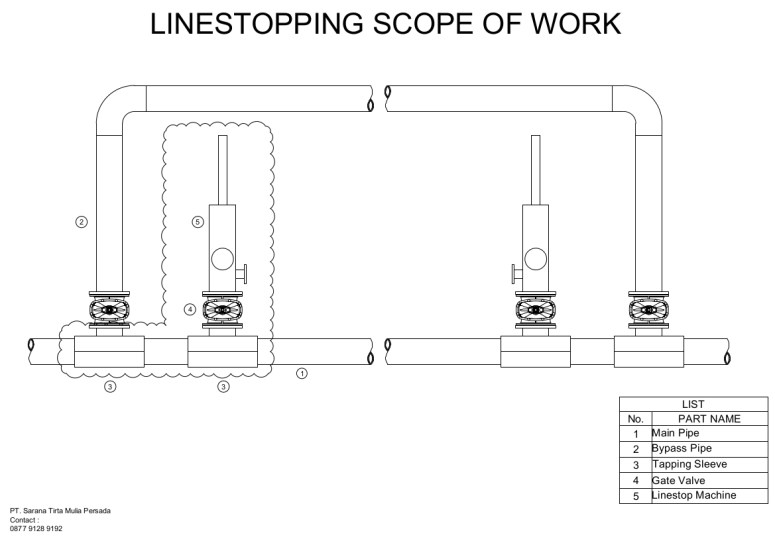

Line stopping or line plugging is a means of isolating a piping system to provide a shut off where none exists (usually for a bypass line, line relocation or valve maintenance / replacement). This process serves as a control, or temporary valve, that can be removed after alterations or valve replacements have been made.

With a hot tap previously made on a line, a line stopper is attached to a temporary valve, and the valve is opened. The line stopper is hydraulically or mechanically pushed into the line to seal the pipe. The main is supported by the line stop sleeve. After performing the necessary service, the stop is removed, and a blind flange is installed on the sleeve.

Considering shutdown costs

How much does it cost to shut down a system? From a financial perspective, cities should consider all of the costs associated with shutting down a system: coordinating meetings with the utility, large water users and construction crew; putting fire trucks on standby; installing temporary above-ground water services; advertising the shutdown; dechlorinating the water; locating and turning control valves; returning to the maps to find back-up valves to shut down because some do not work or cannot be located; returning to the streets to find and operate those valves; advertising a larger shutdown area; losing water revenue; refilling pipes with treated water; purging and flushing; gaining entry to clean plugged water meters; dealing with backflow; handling air trapped in old pipe joints that can cause future main breaks; answering complaints of ruined laundry; turbidity; consumer confidence fallout; and compliance with rules and regulations.